This industry, which enables the global movement of goods worth $10.6 trillion annually, is undergoing a major transformation, with 20 million logistics jobs expected to be automated by 2030. This article, Robotics and AI in Logistics, explores the nature and extent of these changes.

As we know, the global logistics market was valued at $8.96 trillion in 2023; however, credible studies predict that this figure will rise to $21.91 trillion by 2033. This transformation is driven by evolving lifestyles, global population growth, and advancements in automation, artificial intelligence (AI), and next-generation supply chain strategies.

1. Key Changes Robotics & AI Will Bring to Logistics

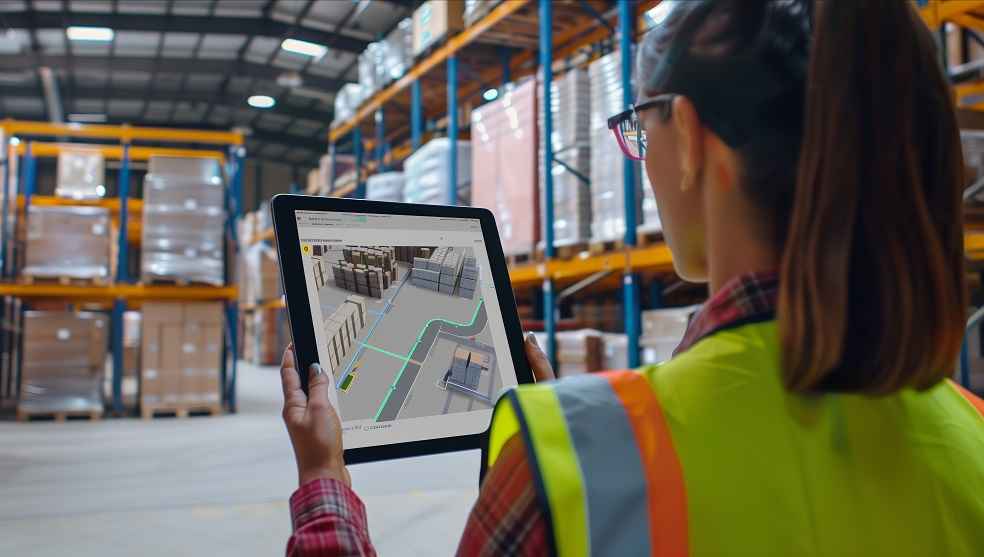

1.1 Automation in Warehousing

Robotics is revolutionizing warehouse operations, with autonomous mobile robots (AMRs) handling picking, packing, and sorting three times faster than humans.

- The warehouse robotics market is valued at USD 6.1 billion in 2023 and is projected to grow at a CAGR of 11.4%, reaching USD 10.5 billion by 2028. (MarketsandMarkets Study).

- Amazon has deployed over 750,000 robots in its fulfillment centers, reducing order processing time by 50%.

- AI-powered inventory management tools predict demand fluctuations with up to 95% accuracy (McKinsey, 2022).

1.2 Autonomous Transportation

Self-driving trucks and drones are shaping the future of freight and last-mile delivery:

- The autonomous trucking market is expected to grow significantly, reaching hundreds of billions in market value by 2030 (PwC).

- Companies like TuSimple and Waymo are testing Level 4 autonomous trucks, reducing fuel costs by 15% and delivery times by 30%.

- Drone delivery programs by UPS and Alphabet’s Wing have cut last-mile costs by up to 40% in rural areas.

1.3 AI-Driven Supply Chain Optimization

AI-powered analytics help logistics firms optimize supply chains and mitigate disruptions:

- 65% of logistics firms use AI for route optimization, reducing fuel consumption by 20% (Gartner, 2023).

- IBM’s Watson Supply Chain has helped companies reduce forecasting errors by up to 50%, saving millions annually.

1.4 Last-Mile Delivery Innovations

With last-mile delivery accounting for 53% of total shipping costs (Capgemini), robotics and AI are addressing this challenge:

- Robotic delivery vehicles and smart lockers streamline urban logistics.

- Startups like Starship Technologies deploy autonomous delivery robots, reducing last-mile costs by 90% compared to human couriers.

2. Benefits of Robotics & AI in Logistics

2.1 Enhanced Efficiency and Speed

- Automated warehouses achieve 50% faster order fulfillment (DHL).

- AI-driven logistics systems operate 24/7, increasing productivity by 30%.

2.2 Cost Reduction

- AI-driven automation lowers labor costs by 20-30% (Boston Consulting Group).

- AI-powered route optimization reduces fuel and maintenance costs by 15-25%.

2.3 Improved Accuracy and Safety

- 99.9% inventory accuracy with RFID and AI tracking (Zebra Technologies).

- 50% fewer workplace injuries in automated warehouses (OSHA).

2.4 Scalability and Flexibility

- Cloud-based AI systems allow real-time adjustments, increasing throughput by 40% during peak seasons.

3. Drawbacks and Challenges

3.1 High Initial Investment

- Implementing warehouse robotics costs $5 million–$15 million, with a 3–5 year ROI period (ABI Research).

- Small and medium-sized enterprises (SMEs) may struggle with capital investment, widening the gap between large and small logistics players.

3.2 Workforce Displacement

- AI and automation could impact millions of logistics jobs by 2030 (World Economic Forum).

- Warehouse workers, truck drivers, and couriers are at the highest risk.

3.3 Technical Limitations

- Autonomous vehicles struggle in extreme weather and unstructured environments.

- AI-based decision-making relies on large datasets, making inaccurate data a risk factor.

3.4 Cybersecurity Risks

- Cyberattacks on AI-driven logistics are increasing, with ransomware attacks rising 150% in 2022 (IBM).

- 68% of logistics firms report cybersecurity risks related to AI deployment.

4. Impact on Human Work: Job Loss vs. Job Transformation

4.1 Job Displacement Trends

- 30% of warehouse roles (e.g., pickers, packers) could be automated by 2030 (McKinsey).

- 1.7 million truck drivers in the U.S. face reduced demand due to self-driving trucks (U.S. Bureau of Labor Statistics).

4.2 Emerging Roles and Reskilling

- 12 million new jobs in AI supervision, robotics maintenance, and data analysis are expected by 2030 (WEF).

- Companies like FedEx invest $200 million annually in reskilling programs for displaced workers.

4.3 The Human Edge

While AI replaces repetitive tasks, roles requiring creativity, crisis management, and human interaction remain critical:

- Supply chain strategists

- AI ethics auditors

- Drone traffic controllers

5. The Future Outlook

By 2040, automation is expected to reach up to 70% in logistics. Key trends include:

- Collaborative robots (cobots) working alongside human employees.

- Blockchain-integrated AI for fraud-resistant, transparent supply chains.

- AI-powered green logistics, potentially reducing carbon emissions by up to 35% (Accenture).

In summary, while automation will reduce some manual roles, it will also create new opportunities. The future workforce in logistics will need skills in AI management, robotics maintenance, and data analytics. This means we must adapt our knowledge and abilities to emerging roles such as AI specialists, drone operators, and robotics engineers.

The workforce must be prepared to embrace and adapt to these changes rather than resist the inevitable robotics and AI revolution in logistics. These technologies drive efficiency, cost savings, and innovation. Although challenges like job displacement and cybersecurity risks exist, the benefits far outweigh the drawbacks.

MOST POPULAR | Global Organic Meat Market Growth and Trends