Researchers from the Chalmers University of Technology in Sweden have made a groundbreaking discovery, pioneering a method that dramatically reduces mercury levels in sulphuric acid, leading to a potential 90% reduction in industrial mercury emissions. The development could have a significant global impact in combating mercury pollution, improving the quality of this globally important chemical, and reducing related health risks.

The world’s most used chemical, sulphuric acid, plays a key role across industries, from paper, pharmaceuticals, and cosmetics, to batteries, detergents, and fertilizers. However, it often contains mercury, one of the most toxic substances known, posing a global environmental challenge.

Until now, no feasible method existed to purify finished sulphuric acid. Björn Wickman, Associate Professor at the Department of Physics at Chalmers and the research leader, said: “With such a radical reduction in the mercury content, we come well below the current limit values. This step is crucial in reducing environmental impact and providing industry with high-quality, pure sulphuric acid.”

Mercury’s Toxic Emissions

Mercury’s dispersion is a global concern due to its volatility, allowing it to spread over vast areas. The heavy metal affects the entire food chain and can damage the brains and central nervous systems of humans and animals.

The United Nations Environment Programme (UNEP) reported a 20% increase in mercury emissions between 2010 and 2015. The increase resulted from human activities such as cement manufacture, small-scale gold mining, coal burning, metal production, and other manufacturing industries. The UNEP further estimates a 450% increase in atmospheric mercury concentrations in the past century.

Wickman asserts that any reduction in mercury emissions will benefit the environment as mercury remains a health threat for thousands of years once released.

Pioneering Method for Mercury Reduction

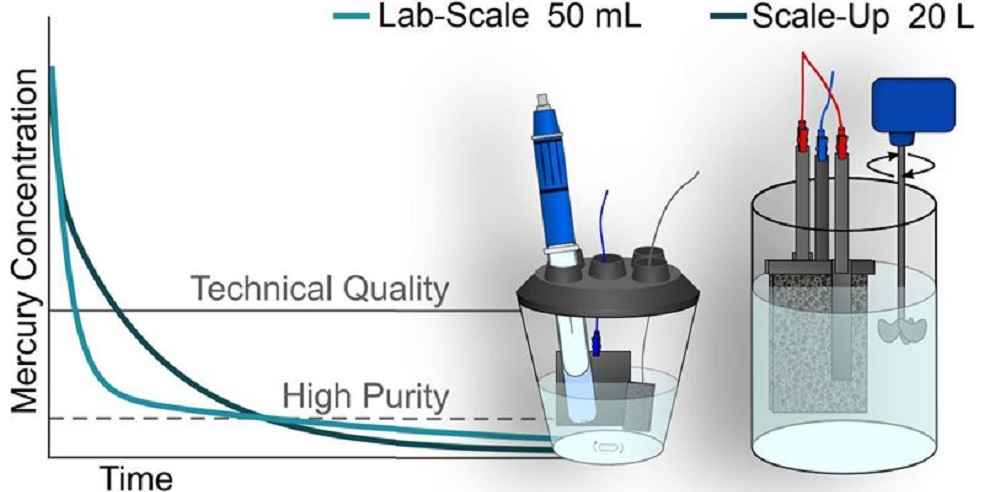

In the past, the research team at Chalmers introduced a method for removing mercury from water using electrochemical processes. The team further developed this technology to remove mercury from concentrated sulphuric acid, showing a reduction of over 90%.

The new method involves a platinum-coated electrode that alloys with mercury, allowing the metal to be safely removed and the electrode to be reused. This innovative process is both effective and energy-efficient.

“We hope to develop a reactor where sulphuric acid can flow and be purified at the same time,” said Vera Roth, a doctoral student at Chalmers and first author of the recently published article.

Potential Global Impact

The process could significantly decrease the mercury content in sulphuric acid, reducing the environmental impact, enhancing the product’s quality, and making industrial operations more cost-effective.

The current acceptable quality for commercial sulphuric acid is below 0.30 milligrams of mercury per kilogram. If the content is below 0.08 milligrams per kilogram, it is considered high purity. The new method brought the mercury content down to 0.02 milligrams per kilogram in the pilot study, setting a new benchmark for sulphuric acid purity.

“The limit values for how much mercury sulphuric acid may contain are based on the technology available today. We hope that with this new method, the legislation around the limit values will be tightened globally,” said Wickman.

The researchers are now aiming to scale the method into a real-world pilot process, anticipating this discovery to make a substantial difference globally.

Funding and Future Steps

The research was funded by Formas and the strategic innovation program Swedish Mining Innovation, a joint venture involving Vinnova, Formas, and the Swedish Energy Agency. Future work will focus on scaling up the method into a pilot project suitable for industrial application.

This innovative method not only provides a potential solution for reducing mercury emissions but also serves as an essential stride toward creating a safer and cleaner environment worldwide. The breakthrough has the potential to transform industries globally and make significant strides in addressing the environmental challenges posed by heavy metals.

BUSINESS GENERAL: Chinese Lithium Giants Expanding Globally for EV Battery Supremacy